The Ahumoana o Aotearoa Spat Research Collective (AASRC) is an industry-led initiative that aims to bring stakeholders and researchers together to address productivity challenges faced by the Greenshell™ mussel (Perna canaliculus) aquaculture industry in Aotearoa New Zealand.

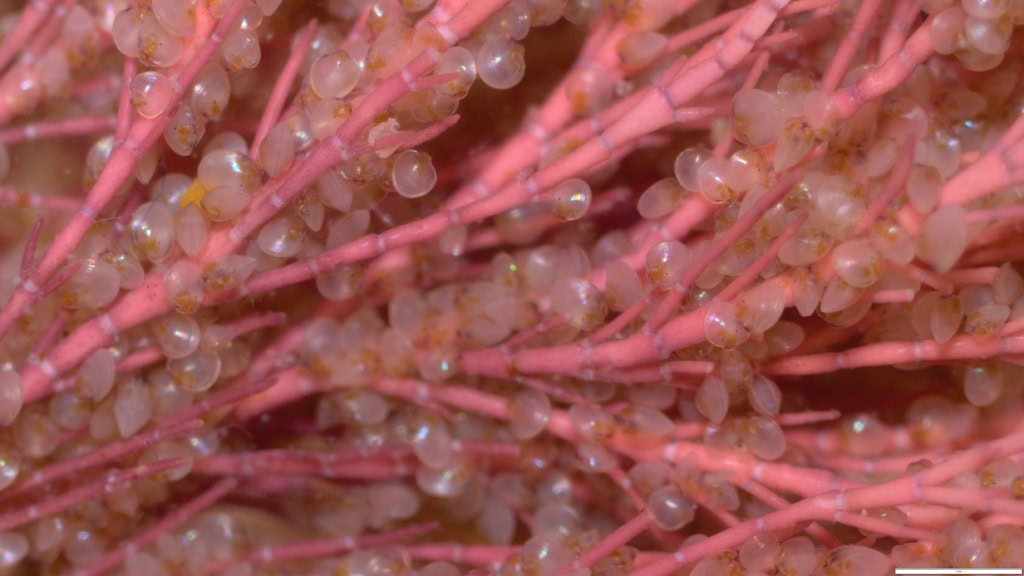

Above, microscopic baby mussels called ‘spat’ are attached to a coralline alga that has washed ashore on 90 Mile Beach in the North of Aotearoa New Zealand. These beach-cast spat, often known as “Kaitaia spat” have historically served as the major source of spat for greenlipped/Greenshell™ mussel (Perna canaliculus) aquaculture.

The first AASRC project, funded by MPI Fisheries NZ (for three years), and supported by Aquaculture New Zealand and the Shellfish Aquaculture Research Platform (ShARP), tackles the issue of inconsistent spat performance across different sites. With extreme variability in the supply of 90-Mile Beach spat in recent years, our focus has been on understanding the environmental characteristics of good nursery sites, with a long-term aim of maximising the efficient use of this precious natural resource. To date, why some sites are better for holding spat, and whether this is consistent over time, is not well known. This may be due, in part, to the high variability among batches of spat and differences in industry practices surrounding their deployment. To address this uncertainty, the project aims to develop a tool in the form of a statistical model that can predict areas that are likely to provide better spat performance (retention and growth) in the months ahead. The model will incorporate new data on spat retention and growth, historic industry data, and a wide variety of environmental data obtained from satellites and sampling in the field.

Above, the Cawthron team working alongside industry to collect mussel spat samples in May 2024

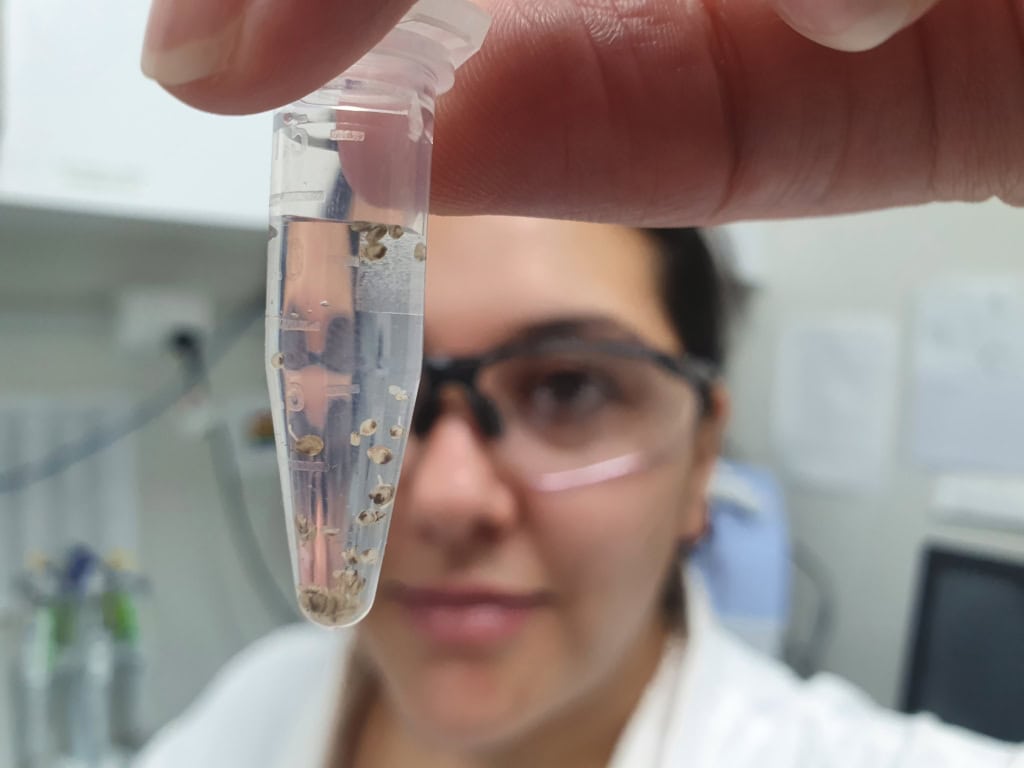

Above, Dr Natali Delorme holds a sample of hatchery reared mussel spat which will be analysed for biochemical composition

The first phase of the AASRC project, has focused on obtaining new data on spat performance across a range of mussel farms and farming regions. Importantly, we have tried to reduce some of the variability in the seeding step by using a single batch of spat and deploying it in a consistent and industry-relevant manner across different sites. The sites were pre-selected by stakeholders and included mussel farms that were considered either good, average, or poor spat nurseries, allowing us to evaluate the industry rating and providing insight into the consistency of spat performance over time.

We have made good progress in the first year of this programme. In May 2024, the first of our spat deployments (Deployment 1 – that was deployed in December 2023) was retrieved from eight mussel farms in Golden Bay and the Marlborough Sounds. We are also excited to report that our second deployment took place at the beginning of October 2024, but this time, we split a single consignment of Kaitaia spat among 19 mussel farms across five mussel growing regions from Banks Peninsula in the south, to Houhora in the far north. These deployments have been highly collaborative events with representatives of thirteen mussel-farming and spat producing companies, Aquaculture NZ, the Marine Farming Association, Cawthron Institute and NIWA, all chipping in and contributing their expertise.

Above, deploying the spat is a coordinated and collaborative team event!

Results from the first year

For Deployment 1, two batches of hatchery-reared spat, kindly provided by SPATnz and Te Huata Ltd, were deployed at ten mussel farms. 200 m of spat holding rope per batch were put out on each farm (see Table below). Temperature loggers were installed, and water was regularly sampled and sent to NIWA for analysis to provide environmental data for each deployment site. Further environmental satellite data will be obtained for each deployment.

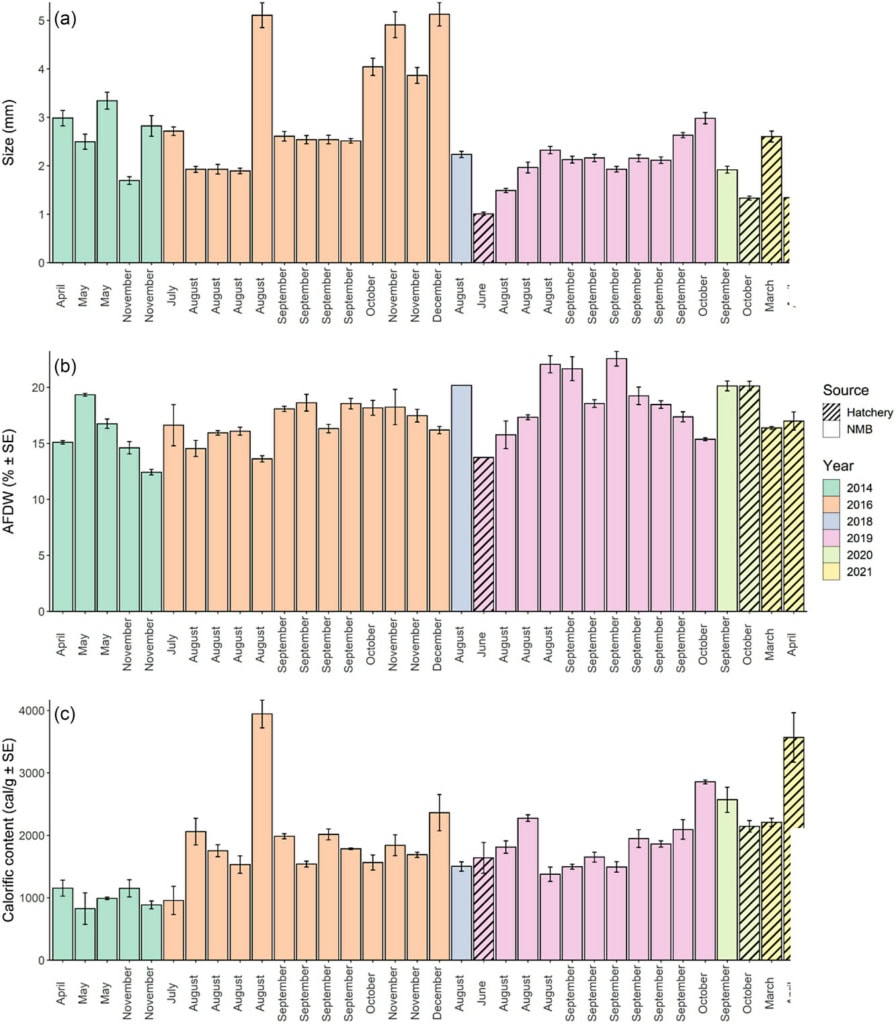

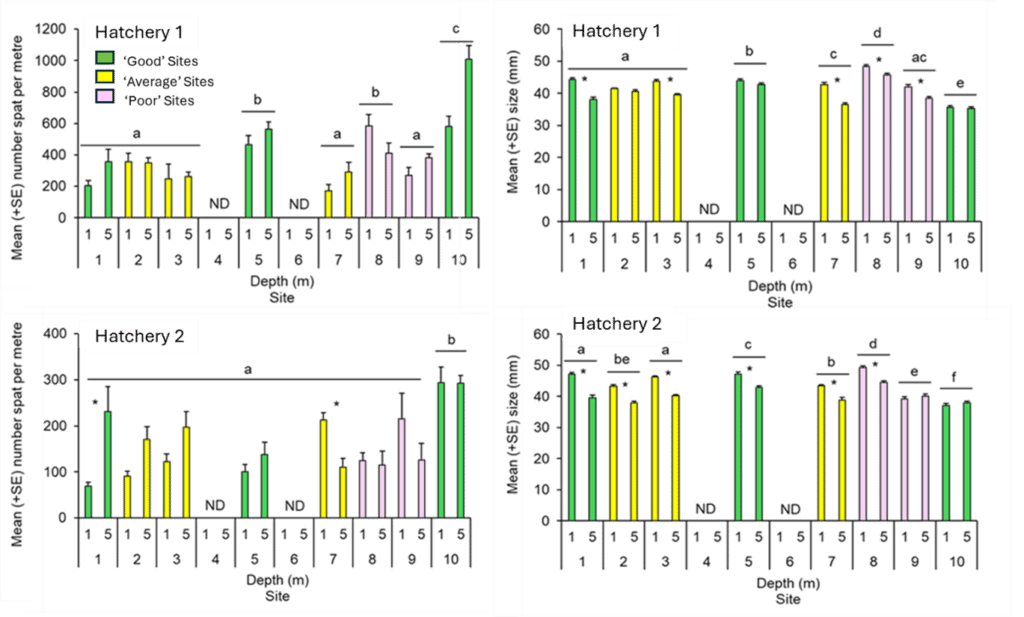

To assess spat performance, we assessed the number of spat per meter of rope (i.e., spat retention), the size of the spat, and their condition. To determine the condition of the spat, we quantified the ratio of the dried meat to shell – with lower values indicating less meat or lower condition, and we assessed the nutritional composition of the tissues in terms of their protein, carbohydrate and lipids. Together, these measures of performance provide a good overview of how farm sites can affect spat performance.

During the six-months of Deployment 1, the mussels from two farms, one in Wainui and one in Anakoha were lost, therefore, we can only report data for eight mussel-farm sites. The remaining mussels were sampled at two different depths at each site (1 and 5 meters deep), in May 2024.

Table 1. The 10 sites used for Deployment 1 of the project and their anecdotal spat performance rating.

| Site # | Location | Anecdotal Rating |

| 1 | AMA 1 (a) | Good |

| 2 | AMA 1 (d) | Average |

| 3 | AMA 2 (q) | Average |

| 4 | Wainui | Good |

| 5 | Croisilles | Good |

| 6 | Anakoha | Good |

| 7 | Clova Bay | Average |

| 8 | Schnapper Point | Poor |

| 9 | Saratoga | Poor |

| 10 | Port Underwood | Good |

Retention was greatest at Port Underwood (site 10) for both batches; however, this site also had the smallest mussels. The largest mussels were found at Schnapper Point (site 8) for both batches. There were no clear patterns in spat retention or size among ‘good’, ‘average’ or ‘poor’ sites but spat were generally smaller when sampled from 5 meters deep compared to 1 m deep.

The condition index (CI) and nutritional composition of the spat varied among sites with CI values ranging from 15% at Croisilles, to 28% at Clova Bay for spat from Hatchery 1, and 16% at AMA 1(a), to 25% at Port Underwood for spat from Hatchery 2, suggesting that site can strongly affect the condition of the spat over six-months.

In terms of nutrition, mussels from Saratoga and Clova Bay showed the greatest amount of fat (lipids) for hatcheries 1 and 2, respectively, likely reflecting the different food and environmental characteristics of the sites.

Above, graph showing mean (average) number of spat per linear meter of grow-out rope for spat from two hatcheries at different farm sites in the top of the South Island six months after deployment. Asterisks indicate significant differences between samples from different depths within a site. Different letters above the bars indicate a significant difference between sites (pooled across depths) for mussels from each hatchery. ND = no data.

The results of this study indicate that the performance of identical batches of spat do vary depending on the mussel farm they are deployed onto. Interestingly, mussels deployed at Schnapper Point also had good retention, and had the highest protein content, despite it being considered a poor nursery farm for spat prior to this experiment. Indeed, there was no evidence to support that the two sites considered to be poor spat sites were any worse (in terms of spat abundance per meter) than the five or six sites that had been given better anecdotal rankings by the mussel-farming industry. However, these are the results of only one study, hence we are keen to reevaluate the performance of these eight mussel farms alongside a further eleven farms with the current deployment of spat (Deployment 2) and beyond.

A huge thanks to the team!

We would like to acknowledge the participants and delegates of the Ahumoana o Aotearoa Spat Research Collective that made this project possible. The team at Aquaculture New Zealand for project management. Kim Thomson of Te Huata Ltd and Ned Wells of the Marine Farming Association for coordinating sampling and the industry-led deployment of spat. Rodney Roberts of SPATnz and Kim Thompson of Te Huata Ltd for contributing the excellent hatchery-reared spat used in the first deployment. Denison Enterprises Ltd, KADH Fishing Company, Reichardt Marine and Westpac Mussels supplied spat and supported with transportation and logistics. Marine Farm Management Ltd, James Marine, Te Aupōuri, NIML, Whakatōhea Mussels, Sanford Ltd, Maclab (NZ) Ltd, Aroma, Clearwater Mussels Ltd, Waimana Marine Limited and Cedenco Foods New Zealand Ltd supplied mussel farm space, vessels, personnel and advice across this project. We are grateful for everyone involved in the planning, deployment, collection of samples, and sample analyses for this project.

The scale of this project is unprecedented and the collaboration and support of all the people mentioned above is truly invaluable. The committed and collaborative approach to deploying the spat in a highly standardised manner, sharing data, know-how and resources like farm space, vessel time, and personnel has established a groundbreaking model for collaborative research.

The Ahumoana o Aotearoa Spat Research Collective will continue to engage with its members and the wider aquaculture community as it develops workstreams for years two and three of this project, and in developing new industry-focused projects for the future.

Contact Dr Natali Delorme

Aquaculture Scientist – Shellfish Stress – Cawthron Institute